Understanding the Lifespan of Canning Equipment

Canning equipment plays a vital role in preserving your favorite foods. However, its effectiveness can wane over time.

To ensure optimal performance, it s essential to understand factors that influence its lifespan. This guide will empower you to identify signs of wear and tear and maintain your tools.

Whether you re a seasoned canner or just starting in home canning, keeping your equipment in prime condition is crucial for success.

Discover how to extend the life of your canning gear!

Contents

- Key Takeaways:

- What is Canning Equipment?

- Factors that Affect the Lifespan of Canning Equipment

- Signs of Wear and Tear

- Extending the Lifespan of Canning Equipment

- Proper Cleaning and Maintenance Techniques

- Upgrading and Replacing Parts

- When to Replace Canning Equipment

- Signs of Irreparable Damage

- Frequently Asked Questions

- What factors affect the lifespan of canning equipment?

- How often should canning equipment be replaced?

- What steps can I take to prolong the lifespan of my canning equipment?

- Is it necessary to replace canning equipment that is not used frequently?

- How can I tell if my canning equipment needs to be replaced?

- Are there any safety concerns with using old or worn canning equipment?

Key Takeaways:

- Quality materials and proper maintenance extend the lifespan of canning equipment.

- Regular cleaning and proper storage help prevent wear and tear.

- Look for signs of irreparable damage; it s time to replace your equipment.

What is Canning Equipment?

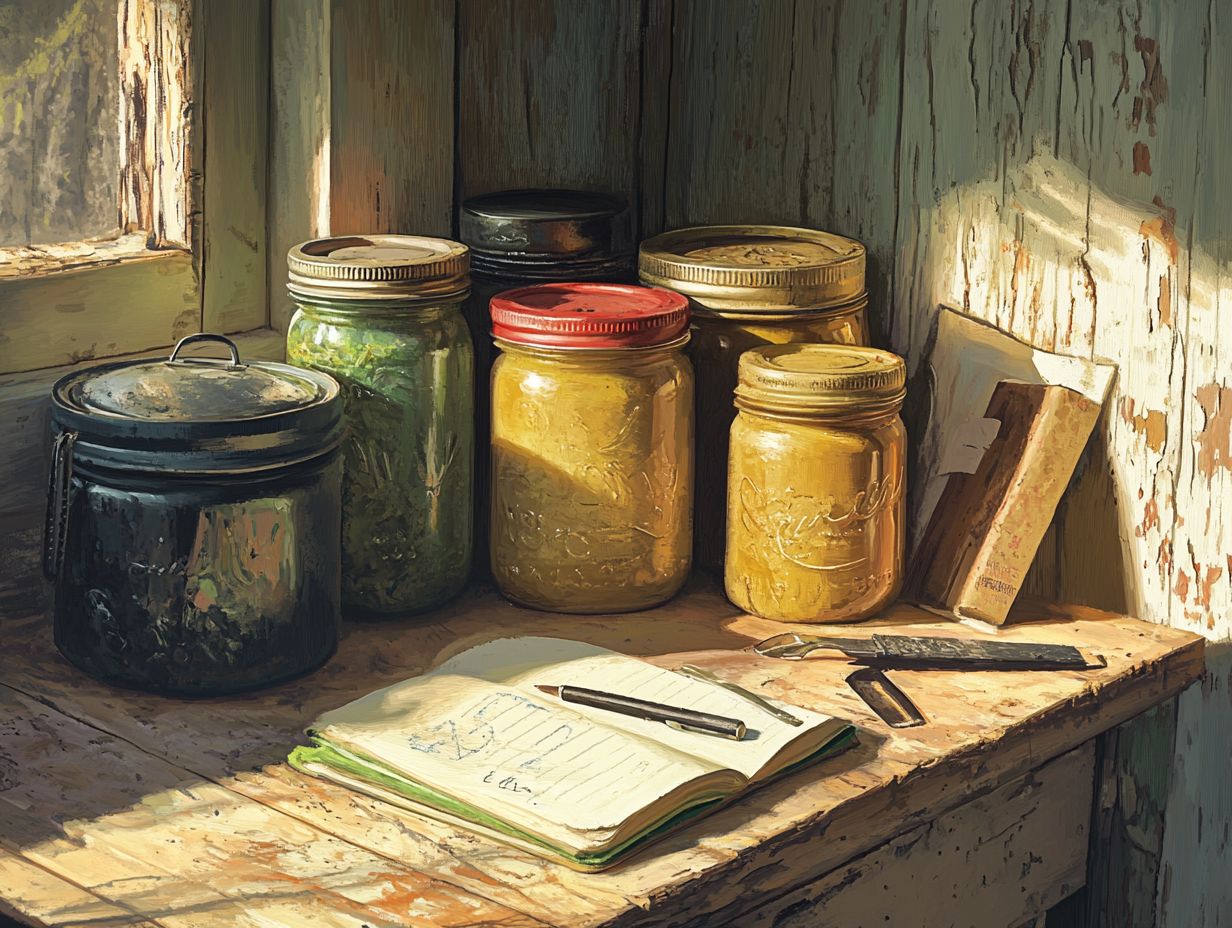

Canning equipment is critical for anyone wanting to preserve food at home. It helps you retain nutrients and keep quality high.

This essential toolkit typically includes pressure canners, jars, lids, and specialized tools for home canning. Following guidelines from the U.S. Department of Agriculture ensures you safely craft a variety of canned goods.

Factors that Affect the Lifespan of Canning Equipment

Your canning equipment s lifespan depends on several key factors. These include the quality of materials, how often you use it, and its maintenance.

Quality of Materials Used

The materials you use for your canning equipment directly impact its durability and effectiveness. Choosing high-quality stainless steel, glass, and silicone ensures safe sealing and freshness over time.

Investing in reliable materials maintains the integrity of your food, reducing the risk of contamination. For example, stainless steel resists rust and corrosion, making it ideal for pressure canners. Glass jars create a safe environment, while silicone lids provide a snug seal that enhances shelf life.

Frequency of Use

Using your canning equipment frequently affects its lifespan. Regular sessions lead to wear and tear, making cleaning and maintenance essential.

To keep your equipment in top shape, clean it right after each session. Disassemble parts and wash them with warm, soapy water, rinsing thoroughly to prevent corrosion.

Regular inspections can help you spot potential issues early. This proactive approach allows for timely repairs or replacements, extending the life of your cherished equipment.

Proper Maintenance and Storage

Proper maintenance and storage are essential for your canning equipment. This ensures its longevity and effectiveness in preserving food.

Follow food safety guidelines, such as cleaning your equipment after each use and storing it in a controlled environment. This prevents quality deterioration and extends the lifespan of your jars and seals.

Meticulously wash jars and lids in hot, soapy water, rinse them thoroughly, and ensure they are completely dry before packing them away. Inspect all seals for any signs of damage or wear; compromised seals can lead to spoilage.

Store your canning supplies in a cool, dark, and dry location. This protects them from mold and moisture and safeguards against heat exposure that can damage metal parts. Adhering to these safety measures enhances the quality of your preserved produce and significantly reduces the risk of foodborne illnesses, including the severe threat of botulism.

Make regular checks a habit! Thoughtful organization of your equipment will lead to delicious and safe home-canned goods.

Signs of Wear and Tear

Spotting signs of wear in your canning equipment is key! It keeps your food safe and delicious. Whether it s visual cues like rust or jar damage, or performance issues such as inadequate sealing, being vigilant can prevent potential foodborne illnesses.

Stay aware of these signs to ensure that your canned goods remain safe and retain their quality for your enjoyment.

Visual Indicators

Visual indicators of wear and tear can manifest as rust on metal components, cracks in glass jars, and damaged seals. These pose risks to food safety and can lead to quality deterioration. Regularly inspecting your canning equipment allows you to identify these issues before they compromise your preserved foods.

For example, rust can create a perfect breeding ground for bacteria, while cracks in glass jars invite microorganisms in and increase the chances of breakage during the canning process. Compromised seals can lead to leaks, allowing air in and spoiling the food inside. Maintaining the integrity of your canning equipment ensures that your food remains both safe and flavorful.

By addressing these indicators promptly, you enhance the overall preservation process, giving you peace of mind as you savor your home-canned delights.

Signs That Your Equipment Needs Attention

Signs like struggling to achieve a proper seal, excessive bubbling in the jar during processing, and inconsistent heating can indicate that your canning equipment isn t quite up to par. This not only jeopardizes food preservation but also heightens the risk of botulism. Regularly monitoring these factors is essential for maintaining food safety.

Keep a vigilant eye on these indicators so you can proactively spot issues before they escalate into major problems. If you hear any unusual sounds or notice steam escaping unexpectedly, halt the operation immediately. This protects the food you re processing and gives you the opportunity to assess and maintain your equipment.

Addressing these irregularities promptly helps ensure compliance with food safety guidelines, reducing the risk of spoilage and contamination, and ultimately leading to much safer canning practices.

Extending the Lifespan of Canning Equipment

Extending the lifespan of your canning equipment is essential for maintaining the quality and safety of your food preservation efforts. By adopting effective cleaning techniques and adhering to a regular maintenance schedule, you can significantly improve the durability and performance of your equipment.

Consider upgrading or replacing worn parts to keep your canning process smooth. Following the guidelines set forth by the USDA and CDC will enhance your canning experience and minimize the risks associated with foodborne illnesses.

Don t wait too long to inspect your equipment; your food’s safety depends on it! Take care of your canning equipment today for delicious, safe meals tomorrow!

Proper Cleaning and Maintenance Techniques

Implementing proper cleaning and maintenance techniques for your canning equipment is vital for ensuring food safety and extending its lifespan. Regularly washing jars and canning tools, sanitizing surfaces, and following food safety guidelines help prevent contamination and preserve the nutrients in your canned goods.

Using a vinegar and water solution can effectively sanitize surfaces and ensure that utensils are free from residues that could harbor bacteria. It s crucial to inspect your equipment for any signs of wear or damage. Compromised seals can lead to spoilage or contamination, increasing the risk of serious issues like botulism in your stored items.

Cleaning up spills promptly and tidying your workspace not only enhances food safety but also supports the longevity of your canning tools. This ensures they remain in optimal condition for your future canning endeavors.

Upgrading and Replacing Parts

Upgrading and replacing parts of your canning equipment can elevate its efficiency and guarantee safe food preservation. As components wear out or as technology progresses, investing in new lids, gaskets, or even a state-of-the-art pressure canner can dramatically improve the nutrient quality retained in your canned goods.

Regularly evaluating these components can help avert potential failures that might compromise both the shelf life and safety of your preserved foods. Relying on outdated or damaged equipment can lead to seals that fail, causing spoilage or contamination. New technologies often feature enhanced safety mechanisms and improved designs that maintain optimal temperature and pressure control, both crucial for food safety.

Transitioning to high-quality, dependable equipment refines the canning process and offers peace of mind, knowing that your preserved items are safe for consumption.

When to Replace Canning Equipment

Understanding when to replace your canning equipment is crucial for maintaining food safety and preventing potential foodborne illnesses. Look for signs of irreparable damage severe rust, cracks in jars, or ineffective seals are clear indicators that it’s time to invest in new equipment.

By doing so, you safeguard your food preservation efforts and ensure the integrity of your cherished canned goods.

Signs of Irreparable Damage

Signs of irreparable damage to your canning equipment include deep rust on metal surfaces, shattered glass jars, or seals that constantly fail. Each of these issues poses significant risks to food safety and preservation. Recognizing these indicators is essential to prevent foodborne illnesses and ensure the integrity of your canned goods.

Such conditions compromise the vacuum seal, which is necessary to keep out air and bacteria, ultimately leading to spoilage. For example, deep rust can flake off and contaminate food, while shattered glass jars pose a physical hazard and compromise the sealing process. Consistently failing seals can allow the growth of botulism or other dangerous bacteria, which is particularly concerning.

Addressing these signs promptly by replacing damaged equipment upholds standards of food preservation and fosters a safe environment for consumption. Taking timely action helps maintain the quality and longevity of stored foods, ensuring you enjoy peace of mind with every jar.

Frequently Asked Questions

What factors affect the lifespan of canning equipment?

The lifespan of canning equipment can be affected by a variety of factors, including frequency of use, maintenance, and quality of materials used.

How often should canning equipment be replaced?

The frequency of replacing canning equipment depends on the factors mentioned above. Generally, high-quality equipment that is well-maintained can last anywhere from 5 to 10 years.

Check your canning equipment regularly to ensure safety and optimal performance. For more tips and resources, explore our website!

What steps can I take to prolong the lifespan of my canning equipment?

Regularly clean and maintain your canning equipment. Use high-quality materials and follow proper steps to can food.

Is it necessary to replace canning equipment that is not used frequently?

Even if you don t use your canning equipment often, maintain it regularly to ensure it lasts. If you don t use it at all for a while, be prepared to replace it due to wear and tear.

How can I tell if my canning equipment needs to be replaced?

Check for significant wear or damage. If it s not working properly or is past its recommended lifespan, it s time for a replacement.

Are there any safety concerns with using old or worn canning equipment?

Old or worn equipment can be unsafe, as it may not seal or process food correctly. Inspect and maintain your canning gear regularly to ensure safe and effective use!